We have designed Commercial Reverse Osmosis Systems (RO) for a wide range of industries, from small companies, restaurants to large health care and manufacturing facilities. It doesn’t matter if you need a traditional system off the shelf or a fully customized system to fit your water purification needs.

Commercial RO Systems

A typical RO System requires pre-filters (all systems come with sediment and carbon pre-filters, additional filtration may be needed based on your water conditions). (RO) membranes are the most common and popular in use.

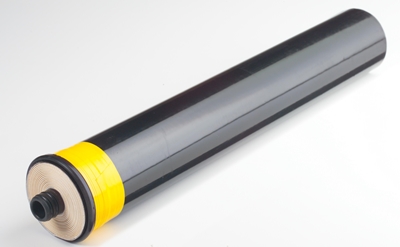

Most are polymer-based and will remove 98% of all dissolved solids present in the feed stream in a single pass. This removal percentage is called Rejection. By taking the product water from one or a number of membranes called the first pass and putting that water through another membrane or group of membranes we create a two-pass system, which can remove well over 99% of the dissolved solids. Product water is called Permeate.

The dissolved solids in water are measured as Total Dissolved Solids (TDS). The TDS meter simply passes a small electrical current between 2 probes and measures how conductive the water is or conversely the resistance of the water. The reading is expressed as Parts Per Million (PPM) of dissolved solids which is essentially the same as milligrams per liter (mg/l).

The typical commercial reverse osmosis systems operate at water pressures between 100-225 psi. Their performance within that range depends upon the type of membrane(s) and the quality of the water being treated. Commercial systems are used in applications that demand large volumes of treated water (150-50,000 gallons) with high levels of purity. The filtration process used by commercial systems is the same as that used by typical residential reverse osmosis systems however, commercial systems become more complicated and expensive due to the addition of such components as pumps, flow gauges, monitors, electrical supplies and more. Commercial systems can be installed in a wall, floor or frame-mounted configuration.

Stages of RO Filtration

Larger reverse osmosis systems typically have a separate carbon and filtration units. Just like having commercial water softeners before the units. RO’s need soft water or the membranes will foul.

The modern RO system is a unit consisting of a sediment pre-filter to remove particulates, turbidity, sand, and rust; an activated carbon pre-filter to remove the chlorine, pesticides, herbicides, disinfectants, and VOCs which might otherwise damage the reverse osmosis membrane; the reverse-osmosis membrane which removes virtually everything such as heavy metals, lead, salt, chromium, and dissolved solids; a storage tank, and some optional water treatment stages.

- Sediment Stage: removes rough particles, sand, and rust.

- Carbon stage: removes chlorine and chemicals which would otherwise damage the TFC reverse osmosis membrane. Multiple carbon stages may be necessary at this point depending on the carbon quality and contact time.

- Reverse osmosis stage: removes dissolved solids And virtually everything larger than the water molecule itself. This is where TDS (total dissolved solids) are removed.

- Storage tank

- Optional or application-specific water treatment stage(s): UV filter to destroy microorganisms, nitrate/arsenic/fluoride/deionization selective filters to remove whatever small amount remains of these contaminants.

Commercial RO Industries

PHARMACEUTICAL:

Water is the most common ingredient in all prescription drugs. Whether for lab testing or manufacturing, the pharmaceutical industry needs the purest water.

AGRICULTURE:

Agriculture is by far the largest use of fresh water in the world—about 69 percent of all freshwater sources. Irrigation water is predominantly obtained via ground water. However, groundwater is either quickly used up by ever-increasing agricultural demand, or contaminated by oils, sewage, or fertilizer seeping through the soil, making them invaluable freshwater source even more scarce.

HOTELS

Hotels can benefit immensely from reverse osmosis (RO) systems coupled with water softeners provide large amounts of clean, purified water for human consumption and use in hotel cafes, restaurants, and bars.

SCHOOLS:

Educational facilities utilize RO systems to provide safe and clean drinking water for students. It can also be used for cafeteria needs and science/lab experiments.

HOSPITALS:

There are many medical uses for reverse osmosis (RO) treated water and water purification systems. Clean, purified, and disinfected water is vital for many medical applications, such as hemodialysis, and to provide sterile water for medical use and treatments. Reverse osmosis (RO) systems, with Electrodeionization (EDI) systems, can be vital to hospitals for filtering high-purity, disinfected water for hospital use, for boiler feed water or for use in foodservice.

POWER AND ENERGY:

Highly purified water is excellent for absorbing heat—this makes it ideal for water cooling technology as it can safely absorb mass amounts of heat, and dispose of it safely, away from the system. If heat isn’t properly disposed of it can potentially cause damage to the generator. These water-cooling systems can also use this same method to bring heat into a system, where it may be needed in industrial processing.

BOILER FEED WATER:

When it comes to boiler feed water, impurities in the water source can cause scaling or even lead to tube failure if left unchecked. Poor quality feed water can increase energy consumption, as well as lead to a reduction in steam quality and purity; and an overall decrease in the production rate and production quality of the final product. Boilers require highly-purified water for proper heat absorption—contaminants and gasses can directly affect how well the boiler feed water performs—which our RO and EDI systems can aptly provide.

FOOD AND BEVERAGE:

For food and beverage processing plants, high quality purified water is required for both production quality and preventative health measures. Reverse osmosis (RO) systems are useful in food manufacturing, processing, and packaging because the reverse osmosis (RO) process can remove many contaminants that can alter the taste and even odor of the water source or food, as well as remove bioorganic and bacteria from the feed water. Although these systems are great at creating purified water, they can still miss certain bacteria and many viruses that can prove harmful in the food and beverage industry. RO systems coupled with UV sterilizers can safely disinfect these water sources for harmless human consumption.

Car Wash:

For many industrial manufacturing plants and commercial businesses, like car washes, surface cleaning and rinsing can be an important part of the process. Water that hasn’t been filtered properly can cause scaling and possibly leave white or gray water spots on freshly cleaned surfaces. This is caused by the calcium and magnesium salts in the source water and is referred to as ‘hard water’; high levels can be found in most untreated drinking water sources as well. RO systems with integrated water softeners can lower the hardness of the treated water by removing the soluble salts that cause scaling—and in turn increase the service quality of many commercial and industrial businesses.

WASTEWATER:

Some industries make use of all kinds of wastewater from contaminated, polluted, or process stream water to grey-water, and even to treated sewage effluent (TSE). These industrial and commercial businesses utilize reverse osmosis (RO) units to treat and sometimes retreat, these water sources. The filtration process then allows the water sources to be used for industrial or commercial applications or disposed of safely and with virtually no environmental harm.

----------------------------------------------------------------------------------------

Small Reverse Osmosis Plant

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

* under standard conditions: TDS< 1500ppm, temperature = 25oC, pH = 7.5

These data are given for information purpose only. They are subject to modifications depending on the water quality. - Suspended solids Lenntech provides all kinds of pre-treatment required before your RO, like multimedia filters, water softeners or de-ironing filters, according to your water analysis and process requirements. Please send us your water analysis for further information. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

---------------------------------------------------------------------------------------------------------

Medium Reverse Osmosis, Demineralisation System

Contact us for turnkey industrial projects - Send your project specification to

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Low energy or high rejection membranes All equipment mounted on stainless steel 304 skid Available in complete Stainless Steel piping Standard control with RO micro-controller and conductivity display Advanced control with flow, pressure, pH and conductivity transmitters for data monitoring, normalisation and SCADA. The system includes: 5 microns filter |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

* under standard conditions: TDS< 1500ppm, temperature = 12oC, pH = 7.5 These data are given for information purpose only. They are subject to modifications depending on the water quality. - Suspended solids Lenntech provides all kinds of pre-treatment required before your RO, like multimedia filters, water softeners or de-ironing filters, according to your water analysis and process requirements. Please send us your water analysis for further information. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

-----------------------------------------------------------------------------------------------------------------

The MARLO MRO-1L Industrial Reverse Osmosis System is a specialized, hybrid design that combines the simple operation and economical features of a traditional 4" style machine with higher product flow rates and industrial appearance of an 8" style machine. The use of single membrane element housings significantly reduce the skid footprint making it the perfect industrial RO system for locations with tight available floor-space.

- Features and Benefits

- 8" x 40" Low-Energy membrane elements (TFC)

- 5-micron sediment pre-filter housing

- Automatic inlet shut-off valve

- Solid-state digital controller (NEMA-4X)

- Product water conductivity monitor

- Operating pressure gauges

- Product, concentrate, and recycle flow meters

- Concentrate and recycle flow control valves

- Low inlet pressure switch with shutdown alarm

OPERATING PARAMETERS

- Operating Pressure: 150-200 psig

- Nominal Recovery: 75%

- Nominal Salt Rejection: 98–99%

- Operating Temperature: 45–85° F

- Design Temperature: 50° F

- Minimum Inlet Pressure: 30 psig

- Control Circuit: 120 VAC, 1-phase, 60 Hz.

MATERIALS OF CONSTRUCTION

- Skid Frame: Powder-coated carbon steel

- Membrane Housings: FRP (300 psig rated)

- Prefilter Housing: Polypropylene

- Low pressure piping: Sch 80 PVC

- High pressure piping: Sch 10 304SS

PUMP AND MOTOR

- Pump: 304/316SS vertical multi-stage centrifugal

- Motor: TEFC, 460 VAC, 3-phase, 60 Hz.

Optional Equipment

- PLC / BMS communication option

- Water softeners and carbon filter pretreatment

- Pretreatment chemical injection systems

- Atmospheric storage tanks with level control

- and re-pressurization pump

- Membrane clean-in-place (CIP) systems

---------------------------------------------------------------------------------------------------

Compact RO Plant

for Drinking water plant, Small Industries, hotels

COMPACT RO: Reverse Osmosis Systems cater to various commercial and small industrial purposes and can be used for well water and tap water purification. System durability ensure output remains constant regardless of fluctuation in raw water source. All units are skid mounted built of stainless steel with compact modules with pre-treatment, post treatment, CIP unit, flowmeters, stainless steel piping with super corrosion resistant coating, UPVC Sch 80 pipes and chemical dosing units.

Applications

Housing & labor camp

Temporary site

Beverage, food industry

Water bottling factory

Hotel, resort

Daily Output: 20,000 Gal - 40,000 Gal

-------------------------------------------------------------------------

Water Maker / Seawater RO

for Offshore / Rigs / Islands, Barges

Producing clean desalinated water for drinking and potable applications in ocean bound ships, vessels and yachts is very important during its voyage. Al Kafaah offers tailored solutions for such marine applications, which mainly operate under a wide range of seawater categories. Al Kafaah specially designs individual units to ensure and height constraints are met.

Applications

Offshore rig

Mobile camp

Remote island

Ship, ocean liner

Yacht, luxury boat

Daily Output: 5,000 Gal - 40,000 Gal

----------------------------------------------------------------------------------------------------------------

reverse osmosis systems for water purification, have been designed to obtain fresh water from brackish water (up to 4.000ppm).

The feeding water could come from tap or well water.

They are able to produce the highest water quality standards and in this range we group productions between 1.7 m3/day to 60 m3/day.

Characteristics

Highly reliable systems.

Manufactured in a stainless steel skid for a longlife.

Compact systems and easy maintenance.

Increasable water production systems.

All the units include, micrometric filters, autoflushing, antiscalant & PLC

Custom units designed in accordance with customer specifications.

Control panel allowing easy reading of water quality and equipment operation status.