Reverse Osmosis Systems

Reverse Osmosis Systems are used to remove unwanted salts and contaminants from a feedwater stream. Reverse osmosis (RO) is the best alternative for high volume/high-quality water treatment. It is commonly used in drinking water, water reuse, and desalination applications. The primary purpose of RO is to produce effluent filtrate (clean water) that has very little in the way of impurities associated with salts and other elements besides water. Reverse Osmosis can remove many types of molecules and ions from solutions, including salts. Systems are designed to achieve removal of TDS, TOC, alkalinity, sodium, chloride, phosphate, iron, manganese, arsenic, boron, and other salts or contaminants based on membrane projections which simulate the rejection of these contaminants by the NF/RO membrane. It is used in both industrial processes and the production of potable water from brackish water or seawater. chemical analysis of the water is used to determine the proper design of the system, including the pre-treatment system. Various RO testing data are analyzed and considered in order to optimize the membrane’s specific applications.

Seawater Reverse Osmosis Systems

Industrial Seawater Reverse Osmosis Systems

ABRAH CO SWRO (SeaWater Reverse Osmosis) system can be designed as part of a Zero Liquid Discharge system for industrial use. ABRAH CO based on its experience in desalination in the middle east recommends using dissolved air flotation DAF and ultrafiltration UF as a pretreatment system in large SWRO units Pretreatments. the treated water containing no suspended solids, oil, or grease. Phosphates/surfactants, salts, and elements contributing to hardness in the influent water are removed. The entire system can be operated automatically based on an integrated PLC control system.

Commerical Seawater Reverse Osmosis Systems

Key RO System Features

- PLC controlled, touch screen operation

- Redundant system capability

- All required instrumentation including flow sensor, conductivity probe, and pressure sensors

- Factory-tested, skid mounted for ease of installation

- VFD for RO feed pumps to maximize efficiency

- Schedule 80 304 SS piping provided for pressures >150 psi

- Samples valves throughout low pressure piping for ease of operation

- Clean In Place (CIP) Chemical cleaning/filtrate flush system included, chlorine feed system provided for control of biological growth and fouling of membrane surfaces

- Complete O&M manuals

System Benefits and Applications

RO System Benefits

Reduction of TDS values >90%

TSS reduction to non-detect

Significant soluble BOD reduction

100% membrane redundancy, if required

Low operator maintenance

Skidded treatment units for easy installation

RO System Design Criteria

Influent Water Temperature: 15-35°C

Power Available: 460V/3Ph/60hz

Total RO Filtrate Flow Rate: up to 1000 GPM

Total RO Feed Flow Rate: up to 1500 GPM

RO System Recovery Rate: 75% or more

RO Applications

Drinking / Potable water purification

Wastewater purification

Industrial applications

Aquariums

Desalination

Sea water to drinking water

Reverse Osmosis water was invited by the US Navy to remove the sodium from ocean water in order to have drinkable water on submarines. That RO system has been refined and enhanced to the systems we have today that are available to commercial and residential customers.

Reverse Osmosis Systems remove TDS from water using pressure through a membrane that separates the water into the concentrate (reject water) and permeate (product water). The systems operate in a pressure range from 200 psi to 1200 psi depending on the application. The higher the TDS, the more pressure is required to overcome osmotic pressure.

Our engineers can design reverse osmosis systems for any application. Because we custom design our systems for each individual project, we are not limited by flow rate, size, or customer specific requirements. Most reverse osmosis systems fall into three main categories; traditional, brackish, or desalination

Traditional RO System

Traditional reverse osmosis systems operate with a feed of 200 psi to 400 psi. This means that a minimal amount of energy is used to pump the feed water through the membranes to overcome the osmotic pressure. The feed TDS levels are typically 100 ppm to 1,000 ppm. Traditional reverse osmosis systems have a configuration that includes a pre-filter, pvc header piping, plc controller, and fiberglass pressure vessels for the membrane housings. Options include stainless steel pressure vessels, stainless steel header piping, plc controller with remote monitoring, controller with touch panel display, design modifications for higher recovery rates, and other items depending on your application.

Where Can I Buy Reverse Osmosis Water?

Robert B. Hill Co has been selling RO systems for decades. No matter what your application, we can install a reverse osmosis system for your company.

Contact us today for pricing and availability.

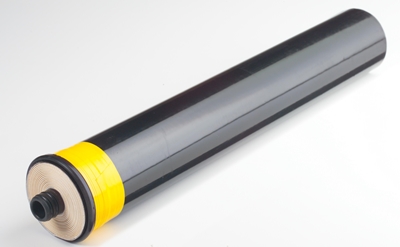

Reverse Osmosis Filters and Membranes

Brackish RO Systems

Brackish reverse osmosis systems tend to operate over 400 psi and require more energy as a higher pressure pump is necessary. Brackish water has higher total dissolved solids than water that is fed through a traditional reverse osmosis system. The feed TDS levels are typically 1,000 ppm to 5,000 ppm. Brackish reverse osmosis systems have a configuration that includes a pre-filter, pvc header piping, plc controller, and fiberglass pressure vessels for the membrane housings. Options include stainless steel pressure vessels, stainless steel header piping, plc controller with remote monitoring, controller with touch panel display, design modifications for higher recovery rates, and other equipment depending on your application.

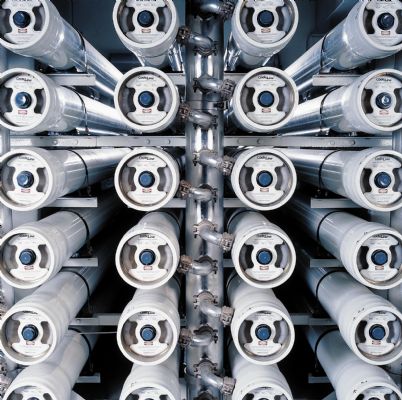

Desalination Water Treatment

Desalination reverse osmosis systems operate at 800 psi to 1200 psi. At 800 psi and above, a special high-pressure pump is required. These pumps not only produce high pressure but need to be made out of special alloys. Because of the increased amount of energy that is required to overcome the osmotic pressure, energy recovery devices are typically used. The feed TDS levels for desalination reverse osmosis systems are typically 5,000 ppm to 40,000 ppm. Because of the high levels of TDS, the piping is made out of stainless steel or a variety of special alloys. Standard components are a plc controller with remote monitoring, touch panel display, and fiberglass pressure vessels.

WATER DESALIATION BY REVERSE OSMOSIS

Brackish and sea water contain a high level of dissolved salts, with TDS from 1.500 to 47.000 mg/1

After a suitable pre-treatment salty water can be desalinated byreverse osmosis (RO) Systems.

Salty water is pumped under high pressure through a polyamide membrane, the water (solvent) passes through the membrane and the dis-solved salts are retained by reason of their different molecular structure. These membranes pass relatively pure water (permeate) and retain concentrated salty water (concentrate)

we can achieve any requested treated water quality for potable/drinking and industrial purposes

CONTAINERIZED REVERSE OSMOSIS

At site only the connections of raw water, power cable to the Container and connection of permeate water outlet from the Container to any tank or points of use should be done.It needs a very simple concrete Foundation for levelling the Container and collecting the drained water

Their hydraulic development is Standard in international power stations with extremely high efficiency. It needs a very simple concrete foundation for levelling the container and collecting the drainded water.

LAY-OUT

one 40 feet container,

2000 m3/d (440.000 gpd)

Reverse Osmosis plant incl. Filter Station,

two containers and high pressure pumps